4oz High Speed PCB Design Service LF-HASL Circuit Board Design

With the development of electronic technology, there is a great

demand on high speed PCB design to work. Because they can work with

integrated circuits at high speeds for most electronic devices,

even quite simple ones. When you design a high speed PCB, it needs

to take some factors and parameters into consideration. What’s

more, you will find that the basic PCB design rules and methods you

have mastered is what you need to learn. Needless to say, it will

be of great assistance to PCB designers in high speed PCB design.

What is high speed PCB design?

High speed PCB design is any design where the integrity of your

signals begins to be impacted by physical characteristics of your

PCB, such as layout, packaging, interconnection, as well as layer

stackup and so on. What’s more, you will come into the world of

high speed PCB design when you start to design the boards and get

into troubles such as delays, crosstalk, reflections, or emissions.

High speed design is so unique because of the attention paid to

these issues. You might be used to designing a simple PCB where you

are mainly in paying attention to component placement and routing.

However, it’s more important to take some factors into

consideration when using a high speed design, such as how close

they are to signals, what width they are going to be, where you are

placing the traces, as well as what kinds of components they are

connected. What’s more, it will achieve a great level for your PCB

design process when you take the factors into considerations.

High speed PCB design skills

1. Know a design software that can offer advanced options

It needs a lot of complex features for high speed designs in your

CAD software. What’s more, there may not have many programs for

hobbyists, and usually it doesn’t have advanced options based on

Web suites. So you need to have a better understanding of a power,

CAD tool.

2. High speed routing

When it comes to high speed traces, a designer needs to know the

rules for essential routing, including not cutting ground planes

and keeping trails short. So prevent digital lines a certain

distance from crosstalk, and shield any interference creating

elements so that damaging the signal integrity.

3. Routing traces with impedance control

It needs impedance matching for some types of signals which are

about 40-120 ohms. And characteristic impedance matched hints are

antennae and many differential pairs.

It’s important for designer to know how to calculate trace width

and layer stack for necessary impedance values. If there is not

correct impedance values, it may make a serious effect on signal,

which will lead to data corruption.

4. Length matching traces

There are many lines in high speed memory buses and interface

buses. The lines can work at quite high frequency, so it’s vital

that the signals need to be from the transmitting terminal to the

receiving terminal at the same time. What’s more, it needs to a

feature called length matching. So most common standards define

tolerance values that need to match length.

5. Minimizing loop area

There are some tips high speed PCB designers need to know that high

frequency signals will lead to some problems of EMI, EMC. So they

need to abide by basic rules such as having continuous ground

planes and reducing loop areas with optimizing current return paths

for traces, as well as putting in many stitching vias.

High speed PCB design considerations

PCB layout is so important

Needless to say, it’s important for final results to have an

efficient PCB fabrication in high speed circuitry. However, there is not PCB layout at first to take into consideration in the process. So there will have

a great effect on design so that achieve the necessary

functionality and succeed in PCB fabrication, such as advanced

planning and abidance by significant factors. What’s more, you need

to deal with the issues before PCB layout, such as the practices of

designing for manufacturing (DFM) and taking extra account for high

speed PCB demands.

When it begins to test or use in PCB fabrication, poor layouts can

lead to performance issues. What’s worse, it will need to spend

more cost and time on redesigning or reworking because evaluating

the PCB failures or performance issues and reassembling prototype

layouts.

Considerations for PCB design

In fact, high speed PCB design has a lot of limits for designer,

because you need to meet the demands of various signal speeds and

other designs. So it needs to take some factors into consideration

if achieving designing the board in high speed circuitry as

follows:

Schematic considerations:as you know, a great schematic can lay a good foundation for PCB

design. So you can treat the schematic differently according to

whether you are an PCB designer or electrical engineer. In general,

it treats the schematic as a communication way that can connect to

the board. But schematic can make a great effect on organizing and

presenting your high speed design. So there are much available

information as possible on the design schematic such as trace

lengths, necessary component placements, the information of PCB

manufacturer and so on.

Trace length tuning: you need to tune the length of the traces to synchronize signal

transmission with data lines when you use a high speed interface.

However the interface may fail at the maximum frequency or will not

work at all as it’s not synchronized. What’s more, the higher the

frequency of the interface is, the higher the length matching

demands are. So you just need to tune the lengths of all traces in

case of a parallel interface. It’s important to look into tuning

those trace lengths to get the desired lengths within a group of

signals.

PCB materials and stack-up demands for high speed: there will have an effect on your high speed design, such as how

the layer stack-up is structured and what materials your PCB is

built from.

High speed placement strategies: it can optimize the component placement with various methods for

high speed design, as well as improve the component footprint

enhancements to achieve high speed, because changing pad dimensions

and component clearances can make an effect on minimizing high

speed connection lengths.

Differential pair and trace length routing: it’s so important to have the routing of differential pairs in a

high speed design so that there is paired signals making it at the

same time.

Crosstalk, impedance control, and parallelism considerations: there are many various forces making a bad effect on your design in

high speed design. What’s more, it needs to take some tips into

consideration, for example how to minimize the influence on your

design.

Understanding stripline and microstrip: in general, it needs to have a various method to routing traces for

high speed designs. If you want to achieve high speed routing,

you’d better have a better understanding of stripline and

microstrip routing techniques.

Routing topologies and best routing practices: in general, if you want to achieve the necessary circuit path for

high speed routing, it needs to use specific shapes or topologies.

What’s more, it is great to explore various methods to route with

trace lengths, escapes, return paths and so on.

Simulators: it has a great benefit from simulation both before the layout

starts, during and afterward for high speed designs. So you should

have a better understanding of your PCB design software to learn

the tips and tricks used to simulate your designs.

How to know if you need a high speed design?

1. It there high speed interface in your board?

A fast method to find out if you need to abide by high speed design

guidelines is to check whether you have high speed interfaces, for

example DDR, PCI-e, or even video interfaces like DVI, HDMI and so

on.

There are some high speed design rules you need to follow for all

these interfaces. What’s more, offer the accurate specifications of

each data in the documentation.

2. The ratio of your trace length to the wavelength of signals

In general, your PCB will certainly need a high speed design if the

wavelength of your message is the same as the trace length. Because

some standards such as DDR require traces that have a length

matched to minimal tolerances.

A great rough figure is that if your trace length and wavelength

can control within one order of each other. Then you’d better check

the high speed designs.

3. PCB with wireless interfaces

As you know, each PCB has an antenna, it needs to design for high

speed signals no matter what through the connector or on the board.

What’s more, onboard antennas also require close impedance to match

tune length.

It will need to connect to the connectors that have a specific

impedance value for circuit boards with SMA connectors or similar.

Conclusion

In a word, learning about high speed PCB design is leaning about a

different engineering filed. Although there are a lot of factors

you need to take into consideration when working on a high speed

design. Luckily, your CAD software for PCB design will give a hand

to you, such as impedance calculators, trace length reporting

options, differential pair routers, as well as other tools.

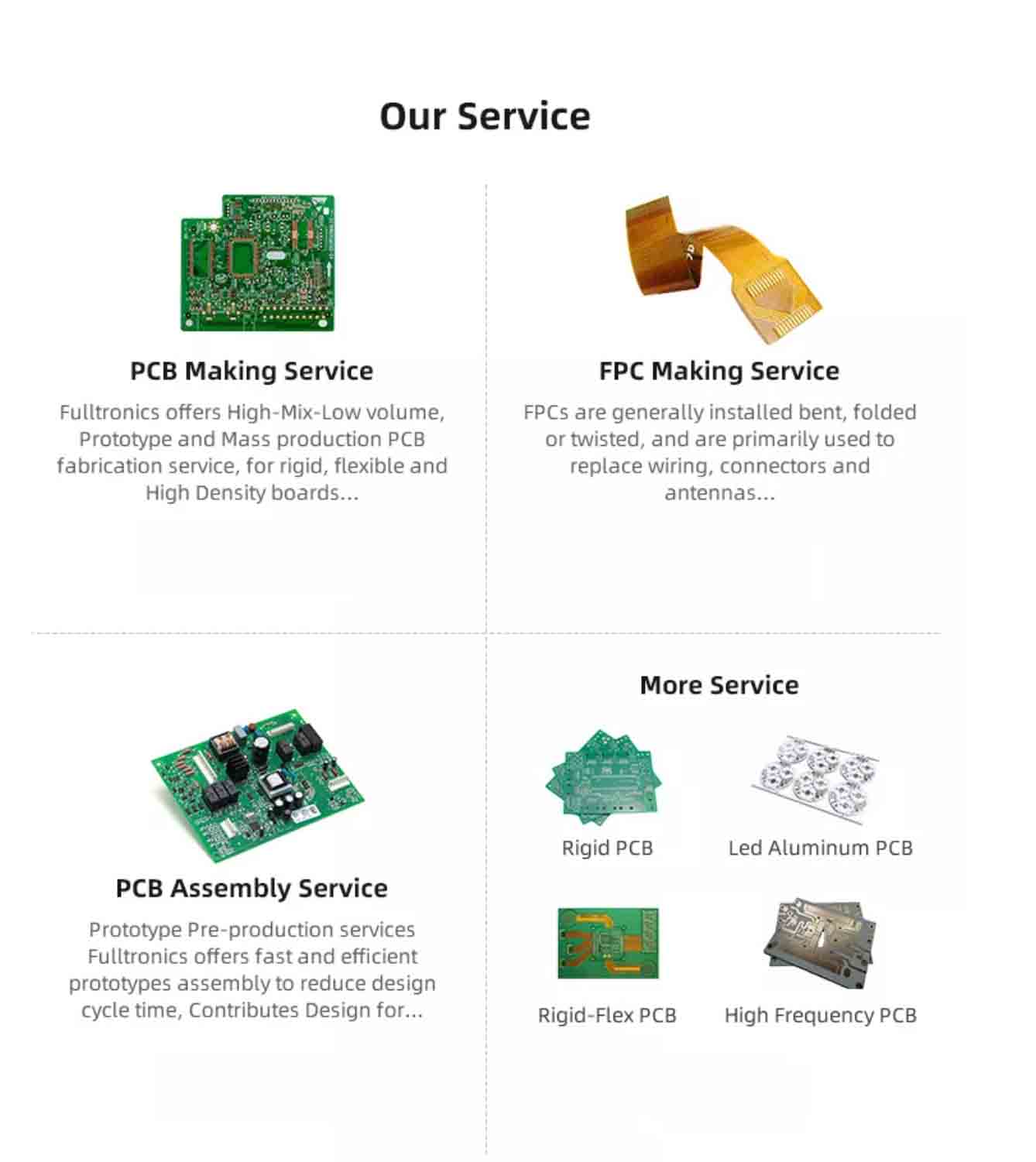

Our Services

1. PCB fabrication.

2. Turnkey PCBA: PCB+components sourcing+SMD and through-hole assembly

3. PCB clone, PCB reverse engineering.

Company Information

Global Well Electronic Inc. is a professional PCB solution supplier

from Shenzhen, China, integrating PCB circuit board production and

processing, STM processing and mounting, PCBA OEM, component

purchasing, PCB/PCBA custom design-production- A comprehensive PCB

circuit board company with one-stop turnkey service of

processing-assembly-finished products. The company has a strong

supply chain system, a professional and efficient collaborative

team, a sound and complete quality control system, and the business

philosophy of honesty and trustworthiness, customer first, and

presents the products to everyone with low prices, reliable

quality, high-quality service and after-sales service. client.

We provide total PCB solutions from PCB design to final mass

production, including PCB fabrication and assembly, component

sourcing, solder paste stencils, conformal coatings, and more.

Serving the global electronics field, including industrial control,

medical electronics, military equipment, power communication,

automotive electronics, AI artificial intelligence, smart home and

other industries.

Our factory located in Shenzhen, and have almost 300

employees, more than 30 production lines include SMT, DIP,

automatic welding, aging test and assembly. We have SMT machines

from Japan and Korea, automatic solder paste printing machines,

solder paste inspection machine(SPI)12 temperature zone reflow

soldering machine, AOI detector, X-RAY detector, wave soldering

machine, EM PCB ,dispenser,laser print machine etc., Different line

configurations can meet requirements from small sample order to

bulk shipment.

Our company has obtained ISO 9001 quality system certification and

ISO 14001 system certification. With multi-testingprocedures, our

products carry out the quality system standard strictly.

Main Equipment:

Company Capability

(1)PCB Technical Specification

| Order Quantity | 1-300,000,30000 Square Meter/Square Meters per Month module

electronic board |

| Layer | 1,2,4,6,upto 24 layer |

| Material | FR-4,glass epoxy,FR4 High Tg,Rohs compliant,Aluminum,Rogers,etc |

| PCB type | Rigid,flexible,rigid-flexible |

| Shape | Any shape: Rectangular,round,slots,cutouts,complex,irregular |

| Max PCB dimensions | 20inch*20inch or 500mm*500mm |

| Thickness | 0.2~4.0mm, Flex 0.01~0.25'' |

| Thickness tolerance | ± 10% |

| Copper thickness | 0.5-4 oz |

| Copper thickness tolerance | ± 0.25oz |

| Surface finish | HASL,Nickle,Imm Gold,Imm Tin,Imm Silver,OSP etc |

| Solder mask | Green, red,white,yellow,blue,black, Double-sided |

| Silk screen | White,yellow,black,or negative, Double-sided or single-sided |

| Silk screen min line width | 0.006'' or 0.15mm |

| Min drill hole diameter | 0.01'',0.25mm.or 10 mil |

| Min trace/gap | 0.075mm or 3mil |

| PCB cutting | Shear,V-score,tab-routed |

(2)Turnkey PCBA Capabilities

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO lines |

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files we need | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) |

| Assembly: Pick-N-Place file |

| PCB panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA |

| Leadless Chip Carriers/CSP |

| Double-sided SMT Assembly |

| Fine Pitch to 0.8mils |

| BGA Repair and Reball |

| Part Removal and Replacement |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

| PCBA process | Drilling-----Exposure-----Plating-----Etaching Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function

Testing-----Temperature - Humidity Testing |

PCB&PCBA Products Show

Company Certifications

Packaging & Shipping

Packing details:

PCBA are packed into plastic bags. Plastic bags are put into small carton. 4 small carton into a big carton.

A big carton: 35×32×40 cm size.

Shipping Express:

FedEx, DHL, UPS, TNT, EMS, private lines, etc.

Air freight, Sea shipping

If you need help on PCB layout, you can contact us and send the

board to us. We also provide Reverse Engineering Service.

We have been providing PCB Manufacture for many years in China,and

we have rich experience in product production and product

assembly.We believe our team will provide high quality and low cost

service for you.

Thank you very much for all your support .

Best Regareds.

PCB or PCBA Files Requests:

1. Gerber files of the bare PCB board

2. BOM (Bill of material) for assembly (please kindly advise us if

there is any acceptablecomponents substitution.)

3. Testing Guide & Test Fixtures if necessary

4. Programming files & Programming tool if necessary

5. Schematic if necessary

FAQ:

Q: What files do you use in PCBA fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position

Q:Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test

procedure?

A: Within 6 hours for PCB quotation and around 24 hours for PCBA

quotation.

Q: How can I know the process of my PCBA production?

A: 7-10 days for PCB production and components purchasing, and 10

days for PCB assembly and Testing

Q: How can I make sure the quality of my PCBA?

A: We ensure that each piece of PCBA products work well before

shipping. We'll test all of them according to your test procedure.

Also if there are any defect items during the shipping, we also can

be free to repair for you.