Many users of printed circuit boards have found ceramic plates to

be superior to conventional boards made from other materials. This

is because they provide a suitable substrate for electronic

circuits having high thermal conductivity and low coefficient of

expansion (CTE). Multi-layer ceramic PCBs are extremely versatile

and can replace complete traditional printed circuit boards with

simple design and higher performance. Ceramic materials play a key

role in electronic components.

Ceramic substrates such as aluminum oxide, aluminum nitride, and

tantalum oxide are highly thermally conductive materials that

rapidly and efficiently transfer heat away from hot spots to

dissipate heat throughout the surface. PCB material (FR-4) is epoxy

based and has poor thermal conductivity leading to hot spots, which

reduces the lifetime of most semiconductor junctions.

In addition to the enviable thermal properties and coefficient of

expansion, ceramic circuit board can operate at operating

temperatures up to 350 degrees Celsius, resulting in smaller

package sizes, better high frequency performance, and a sealed

package that does not absorb water.

According to different manufacturing methods, there are currently

three basic types of ceramic PCB plates:

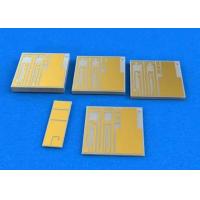

A) Thick film ceramic PCB Board

Thick film ceramic PCB: With this technology, the thickness of the

conductor layer exceeds 10 microns, which is thicker than the spray

technology. The conductor is silver or gold palladium and is

printed on a ceramic substrate. More thick film ceramic PCB.

B) Thin film ceramic PCB

Thin film technology ceramic PCB: Since the thickness of the

resistor and the conductor film is less than 10 μm and the film is

sprayed on the ceramic substrate, it is named as a thin film

ceramic plate. More suitable for thin film ceramic PCB.

C) DCB ceramic PCB

The DCB (Direct Copper Bonding) technique represents a special

process in which a copper foil and a core (Al2O3 or AlN) are bonded

directly on one or both sides at a suitable elevated temperature

and pressure. More DCB ceramic PCB.

Materials - Aluminum Nitride and Alumina

Ceramic PCBs are usually made of metal cores. For high thermal

conductivity, aluminum nitride sheets are ideal for providing over

150 w / mK. However, due to the high price of aluminum nitride

sheets, those who choose cheaper ceramic PCBs may find themselves

using alumina sheets, which provide about 18-36w / mK. Both types

will provide better thermal performance than metal core printed

circuit boards because no electrical layer is required between the

core and the circuit.

The use of silver as a print mark - covered with glass for

protection - will further increase the thermal conductivity (406 W

/ mK). Other ceramic material options include boron nitride,

tantalum oxide and silicon carbide. Due to the high operating

temperature, the ceramic plates are not finished with OSP, HASL or

other conventional surface treatments. However, if silver corrosion

can be a problem, such as in a high sulfur environment, you can use

a gold-plated ceramic printed circuit board to protect the exposed

pad.

Ceramic PCB thermal conductivity

High ceramic PCB thermal conductivity may be the main reason why

more industries turn to ceramics in their printed circuit boards

and packages because this material has significant advantages over

plastics in this respect. Better CTE matching and hermetic sealing

will only increase the attractiveness of these materials. The

challenge is that these materials, as well as the boards produced

by ceramic PCB manufacturers, are much more expensive than

traditional printed circuit board materials, and the materials of

traditional printed circuit boards can be greatly increased in

high-volume work. However, the benefits of ceramic plates and the

need to improve thermal conductivity are so great that companies in

any relevant industry that can afford to use ceramic plates may do

so as necessary.

While we can estimate the level of thermal conductivity that each

ceramic plate can provide, the final value will vary depending on

the manufacturing process and the grain size and composition.

The most popular, despite the expensive ceramic - aluminum nitride

- has a thermal conductivity that many people think is more than

150 W / mK, usually about 180 W / mK. However, studies have found

values ranging from 80 W / mK to 200 W / mK at room temperature,

and when approaching 100 degrees Celsius, the value drops by more

than a third. Other thermal ranges that we can identify at room

temperature include alumina of 18-36 W / mK, yttrium oxide of

184-300, boron nitride of 15-600, and silicon carbide of 70-210.

Ceramic PCB application

Industries that require higher frequency connections and good heat

resistance can benefit from ceramic PCBs. The main industries that

ceramic PCBs can serve include: high-power circuits, chip-on-board

modules, aerospace and heavy-duty equipment, automotive, medical

equipment, heavy machinery, high-power transistors and transistor

arrays, solar cell substrates, and other power applications such as

DC conversion. And voltage regulator

PCB advantages:

- R&D team support

- UL, RoHS,ISO9001,SGS

- IPC class2

- Advanced production line and promtly delivery.

- Honest Credibility in China.

- Professional and abundant experience in PCB

- Competitive price and good quality.

- Excellent after-sales service

PCB showcase:

Our Services

1. PCB fabrication.

2. Turnkey PCBA: PCB+components sourcing+SMD and through-hole

assembly

3. PCB clone, PCB reverse engineering.

PCB or PCBA Files Requests:

1. Gerber files of the bare PCB board

2. BOM (Bill of material) for assembly (please kindly advise us if

there is any acceptablecomponents substitution.)

3. Testing Guide & Test Fixtures if necessary

4. Programming files & Programming tool if necessary

5. Schematic if necessary

Company Information

Global Well Electronic Inc. is a professional PCB solution supplier

from Shenzhen, China, integrating PCB circuit board production and

processing, STM processing and mounting, PCBA OEM, component

purchasing, PCB/PCBA custom design-production- A comprehensive PCB

circuit board company with one-stop turnkey service of

processing-assembly-finished products. The company has a strong

supply chain system, a professional and efficient collaborative

team, a sound and complete quality control system, and the business

philosophy of honesty and trustworthiness, customer first, and

presents the products to everyone with low prices, reliable

quality, high-quality service and after-sales service. client.

We provide total PCB solutions from PCB design to final mass

production, including PCB fabrication and assembly, component

sourcing, solder paste stencils, conformal coatings, and more.

Serving the global electronics field, including industrial control,

medical electronics, military equipment, power communication,

automotive electronics, AI artificial intelligence, smart home and

other industries.

Our factory located in Shenzhen, and have almost 300 employees,

more than 30 production lines include SMT, DIP, automatic welding,

aging test and assembly. We have SMT machines from Japan and Korea,

automatic solder paste printing machines, solder paste inspection

machine(SPI)12 temperature zone reflow soldering machine, AOI

detector, X-RAY detector, wave soldering machine, EM PCB

,dispenser,laser print machine etc., Different line configurations

can meet requirements from small sample order to bulk shipment.

Our company has obtained ISO 9001 quality system certification and

ISO 14001 system certification. With multi-testingprocedures, our

products carry out the quality system standard strictly.

Main Equipment:

PCB Technical Specification

(1) PCB Technical Specification

| Order Quantity | 1-300,000,30000 Square Meter/Square Meters per Month module

electronic board |

| Layer | 1,2,4,6,upto 40 layer |

| Material | FR-4,glass epoxy,FR4 High Tg,Rohs compliant,Aluminum,Rogers,etc |

| PCB type | Rigid,flexible,rigid-flexible |

| Shape | Any shape: Rectangular,round,slots,cutouts,complex,irregular |

| Max PCB dimensions | 20inch*20inch or 500mm*500mm |

| Thickness | 0.2~4.0mm, Flex 0.01~0.25'' |

| Thickness tolerance | ± 10% |

| Copper thickness | 0.5-4 oz |

| Copper thickness tolerance | ± 0.25oz |

| Surface finish | HASL,Nickle,Imm Gold,Imm Tin,Imm Silver,OSP etc |

| Solder mask | Green, red,white,yellow,blue,black, Double-sided |

| Silk screen | White,yellow,black,or negative, Double-sided or single-sided |

| Silk screen min line width | 0.006'' or 0.15mm |

| Min drill hole diameter | 0.01'',0.25mm.or 10 mil |

| Min trace/gap | 0.075mm or 3mil |

| PCB cutting | Shear,V-score,tab-routed |

(2) Turnkey PCBA Capabilities

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO lines |

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files we need | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) |

| Assembly: Pick-N-Place file |

| PCB panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA |

| Leadless Chip Carriers/CSP |

| Double-sided SMT Assembly |

| Fine Pitch to 0.8mils |

| BGA Repair and Reball |

| Part Removal and Replacement |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

| PCBA process | Drilling-----Exposure-----Plating-----Etaching Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function

Testing-----Temperature - Humidity Testing |

PCB&PCBA Products Show

Company Certifications

Packaging & Shipping

Packing details:

PCBA are packed into plastic bags. Plastic bags are put into small

carton. 4 small carton into a big carton.

A big carton: 35×32×40 cm size.

Shipping Express:

FedEx, DHL, UPS, TNT, EMS, private lines, etc.

Air freight, Sea shipping

If you need help on PCB layout, you can contact us and send the

board to us. We also provide Reverse Engineering Service.

We have been providing PCB Manufacture for many years in China,and

we have rich experience in product production and product

assembly.We believe our team will provide high quality and low cost

service for you.

Thank you very much for all your support .

Best Regareds.

AFQ:

A:Yes we are manufacturer

Q:Do you provide samples?

A:Yes we can provide free samples,price and shipping cost open for

negotiation

Q:How do you ensure the quality of your products

A:We will burn into file and test the product and ship it after

confirming that there is no problem

Q:What certificates does this product have

A:We have CE,FCC,ROHS certified

Q:What about OEM and ODM?

A:We accept OEM and ODM orders,MOQ is open for discussion

Q:What is delivery terms and time?

A:We use FOB terms and ship the goods in 7-30days depend on your

order quanlity,customization